At Blackbird Motors we offer you the finest and most up to date replacement outboards and powerheads available.

We have the lasted and greatest technology that money can buy!

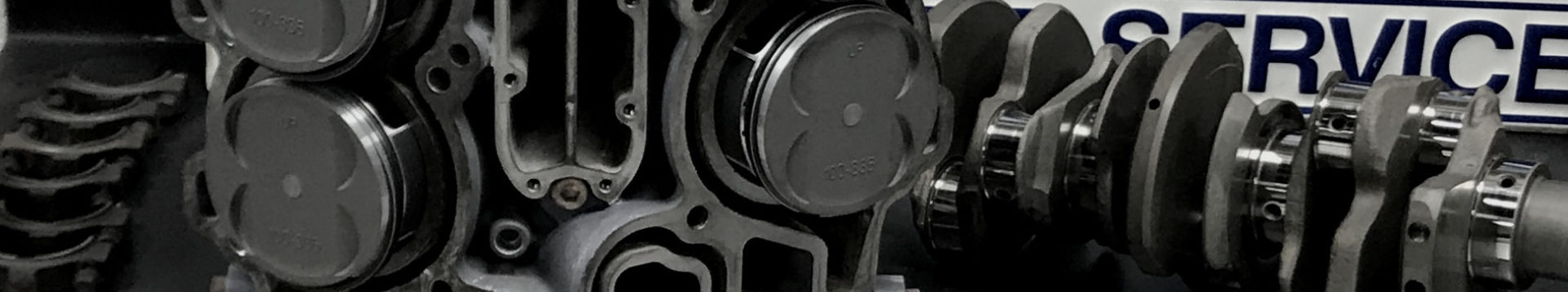

All remanufactured motors and powerheads have been:

-

Hot, high-pressure cleaned with Cuda Ultra-High-Pressure Washer

-

Block inspected, then bored with a Rottler Computer Assist Boring Machine

-

Machined as necessary all block surfaces

-

Chamfer all ports

-

Rottler computer assisted diamond honed to fit all cylinders with new pistons and rings

-

Final ultrasonic cleaning of block assembly

-

All end gaps checked with new pistons, wrist pins, and bearing package

-

Crankshaft inspected for damages and fit

-

Crankshaft repaired or replaced as necessary

-

Final inspection prior to assembly

The Gleason welder allows us to weld/buildup material on the journal before grinding it back down to the proper tolerances. This way we can create a strong repair in a journal that is soft or has pits/small cracks.

We have the ability to perform ultrasonic cleaning on injectors. This back flush procedure provides the most thorough cleaning possible. We can then test each injector’s spray pattern and flow rate to ensure top performance.

As part of the re-manufacturing processes the block and many other parts are thoroughly cleaned in our Cuda pressure washing system.